TragenFlex Inc. is committed to serve the small and large scale commercial clients with top-notch conveyor system and ware washing equipment. Whether your requirements are energy and labor savings, better operational ergonomics, or streamlining your current process, we are here to help.

TragenFlex Inc. is committed to serve the small and large scale commercial clients with top-notch conveyor system and ware washing equipment. Whether your requirements are energy and labor savings, better operational ergonomics, or streamlining your current process, we are here to help.

Our Product Process & Approach

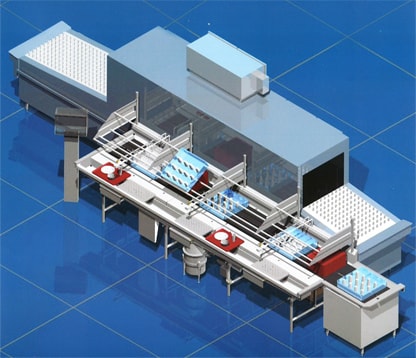

When there is an influx of large volume of trays coming in a short period of time, such as employee and student dining, the tray accumulator would be best for this kind of application. With its unique multi-tier design, it is capable of accumulating trays 5 tiles more than a conventional belt. Below the tray accumulator is an integrated soiled breakdown table, which the operators can conveniently use to strip the soiled trays on the spot and transfer the loaded dish racks to the dish machine using the conveyor behind the waste trough.

A variable speed conveyor brings the soiled trays from the drop off to the dishrooms. Speed can be adjusted by the operator for peak and slow periods. At the end of the tray line are the PVC rollers and landing area to accumulate soiled trays. As an option, a photo electric sensor can be incorporated at the tray drop to index the trays into the dishroom, thus achieving maximum accumulation of trays. A pre-rinse sink is provided for the operator to rinse off the dishes, minimizing the excessive food soiled entering the dish machine.

Our bussing system handles large volume of soiled ware with ease. Food wastes are dropped into the waste trough for automatic removal by a disposer or Pulper. Above the waste trough is the rack shelf for all the rackable items such as cups and glasses. The accumulation conveyor advances the sorted dishware and dish racks, as required by the operator, to the load end of dish machine for washing. The deferred loading of the accumulated dishes and dish racks help reduce the water and energy consumption of the flight type dish machine.

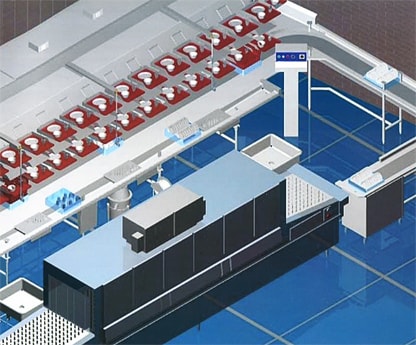

Behind the waste trough is a motorized conveyor which carries loaded dish racks to the dish machine automatically. The two tier shelf above the soiled dishtable utilizes the vertical space as much as possible for cup/glass racks and storage, leaving the prime space in dishroom for the other equipment. The accessories such as pre-rinse sprays, hose clean up station and mobile soak are productive enhancements for the operators using the system.

Behind the waste trough is a motorized conveyor which carries loaded dish racks to the dish machine automatically. The two tier shelf above the soiled dishtable utilizes the vertical space as much as possible for cup/glass racks and storage, leaving the prime space in dishroom for the other equipment. The accessories such as pre-rinse sprays, hose clean up station and mobile soak are productive enhancements for the operators using the system.

The clean roller table is designed to conform to any tight space. The durable PVC rollers reduce friction and help the dish racks move with ease. The elevated position of the rollers above the stainless steel pan allows air to circulate top and bottom of dish racks, drying the dishes a lot faster. Maximum accumulation is achieved when the limit switch is activated by the accumulated dish racks at the end of the table.